Ok there is no particular advantage to doing this but we all like a challenge. LOL

At the beginning of 2010 I undertook a wet to dry clutch conversion on my 620 DD bike. I had great success with the exception of creating a leak free seal between the output shaft and the clutch push rod. Although I raced all year with the conversion it was prone to regular oil/leak seal changes.

I decided the time had come to have another go at a MK2 version.

I picked up a later 600 motor off steeevooo one of the forum users (Bradders old bike) as Louise’s M600 is the earlier wet clutch version and cannot be converted.

The conversion is (reasonably) straight forward as regards parts,

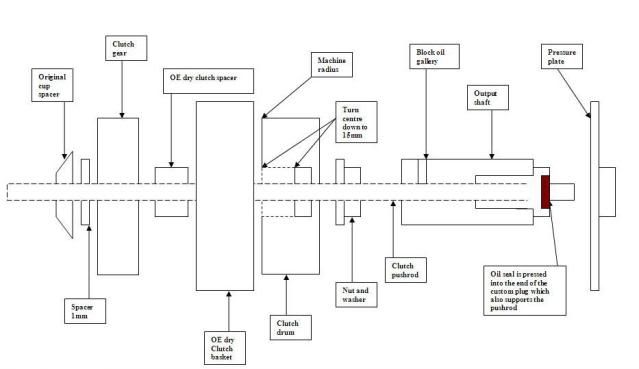

1. Matched pair of dry clutch and crank gears (and the oil pump gear if yours does not match the crank gear)

2. OE dry clutch casing

3. 1mm thick spacer for behind the clutch gear

4. OE dry clutch spacer for behind the clutch drum

5. OE dry clutch basket

6. OE dry clutch plates (stacked accordingly)

7. OE or after market dry clutch pressure plate

8. Dry clutch alloy racing or after market drum. This needs to be so as the original multi part dry clutch drum will not fit the wet clutch output shaft. You ca use the wet clutch drum and pressure plate however, the pcd of the wet clutch basket spring mounting points are different to the dry clutch which prevents the use of an after market pressure plate. The drum centre also needs to be turned down to a depth of 15mm allowing the retaining nut and locking washer to fit.

9. New longer push rod (had to make this)

10. The oil seal. Now some of the 620 motors have an Allen bolt behind the sprocket which enables you to block off the oil gallery to the clutch by fabricating a blank. The alternative (in my case) was to create a better designed seal around the push rod. This seal would also have to support the push rod when the clutch is open (the OE dry clutch has a small bearing and seal in the end of the output shaft). I was able to purchase a 12x8x3 Viton oil seal for £3. I machined an aluminium plug which retains the oil seal and is an interference fit into the end of the output shaft thus giving support to the push rod when the clutch is open.

Finally there is a small oil gallery in the output shaft which I blocked off with plastic metal

Unfortunately I did not take any pictures on assembly. However, the basic drawing gives you the general idea and after the bikes first outing next year I will be dismantling the clutch to inspect it and I will take some then.

Hopefully the new seal design will be more robust than the one I used last year.