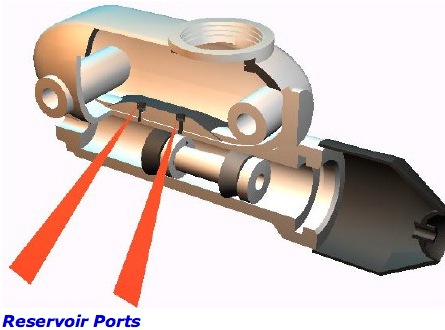

My guess is that one or both master cylinder reservoir ports are partially or fully plugged and the fluid can't return to the reservoir when the fluid heats up.

So when the fluid expands it pressurizes the system and either leaks past the slave cylinder seal or pushes the pushrod causing slippage. First it pushed past the seal, but because it couldn't get by the NEW seal it moved the slave cylinder and therefore the pushrod. Just a millimeter or two is all it takes.

This would also account for the moving engagement point at the lever.

An alternative explanation is that someone adjusted the MC piston stroke incorrectly and the return port is being covered by the MC piston.

Properly adjusted, there should be a 5-10% dead-band of the full lever movement before there is pull resistance felt at the lever. This freeplay is necessary to prevent covering the port as the piston seal expands normally over time, and to avoid placing the piston seal rest location (where corrosion occurs) right at the return port orifice.

Once adjusted, the manufacturer places a potting compound over the screw adjuster to prevent accidental or incorrect adjustment. Check to see if the potting compound has been removed.